How can I pay for my job?

Garagefeet Floor Coatings accepts cash, check & ACH transfer

without any additional fee's.

Credit card fee's will be applied.

Myths about lifetime warranties

What is your warranty?

Other companies offer "lifetime" warranties only to find out it is for the lifetime you own the home. Our warranty covers the floor so when you sell your property, the warranty stays with the house. We realize that you can't take the floor with you!

Why can't I use garage and porch paint on my floor?

You can paint your garage floor with off-the-shelf paint, but you will be disappointed with its performance. Unless you went to great lengths to properly acid etch or mechanically prep the floor before painting, you will get hot tire transfer, peeling, fading, or delamination. Regular paints, even most off-the-shelf epoxies, are not designed to take the abuse that a professionally installed polymer floor can. We use only commercial grade coatings to ensure many years of satisfaction with your floor.

How long does it take to install an epoxy floor?

The time it takes to install a polymer floor depends on several factors. Temperature, humidity, substrate prep, floor size, location, and the system selected all play a factor in the time it takes to install the epoxy. For example, the popular three-coat system (epoxy primer, epoxy basecoat, urethane topcoat) installed in a 400 square foot garage in January here in Southwest Florida may take as little as three days. However, this same system installed in August may take 5 or more days because afternoon showers and high humidity is the norm, and the install steps are adjusted accordingly. Some small installations, such as sheds or trailers, may only take one day using fast cure, two-coat systems.

When can we use the new floor after its installed?

Most flooring systems we use allow foot traffic after 24 hours and vehicle/equipment traffic in 4 to 7 days after the installation is complete. Some high performance systems used in commercial installations have a quicker turnaround rate, using super-fast-cure epoxies.

Do you use acid etching or grinding to prep a floor for epoxy?

We almost always use mechanical grinding to prep our floors. We use diamond segmented grinding plates on a low speed floor machines, which is connected to a dust collection system. Grinding removes the laitance (thin top coat) from the concrete to open the pores and allow excellent adhesion of the epoxy primer. It also works to level rough floors.

Acid etching requires handling hazardous materials and using water on the floor that delays the installation of the primer coat until the floor is completely dry. Etching also does not work well if a sealer was used on the floor, or if oil or other chemicals stains are present. Acid etching has no leveling properties and can be dangerous to work with, aside from the fact that it stinks. Combine these faults with goverment regulation of how acid is stored and transported and its not difficult to see why we don't use it unless we have too. However, when properly used on certain floors, acid etching can be a viable option to expensive concrete grinding machines.

Does the epoxy emit foul odors during the installation process?

Great advancements in the solvent-based epoxy manufacturing process has resulted in epoxies with little or no odor, many of which are government VOC (volatile organic compound) compliant. Some of the urethanes we use do emit a noticable odor during installation, but the odors disipate during the curing process. We work in only well-ventilated areas and if the work area adjoins an occupied area, we can install a vapor barrier to reduce the intrusion of odors into that area. New, low VOC urethanes are now available but are more expensive. In some cases, low-VOC, water based epoxies can be used as an alternative to solvent-based polymers.

Explain cement-based coatings.

Cement-based coatings are outdoor polymers that have characteristics similar to cement, and are usually 2 to 10 times thicker than ordinary paints. These polymers are mostly used to cover and restore concrete patios and pool decks that are in rough shape. Using these coatings is like adding another thin layer of concrete to hide cracks, pits, stains, and other damage. Also, these coatings are permeable, meaning they breathe, allowing trapped moisture to escape. They are UV stable with excellent color retention, and come in a multitude of colors. As an example, if your patio or pool deck is in generally good shape with a few cracks and pits, we would recommend Gulf Sythetics Concrete Rivive. If your patio/pool deck is in bad shape and you are considering total replacement, we might recommend Rustoleum Restore 10X, and extremely thick coating that just might save the day and eliminate the need for costly concrete replacement. These same coatings are also available for wood repair.

For patios and pool decks that are new or in excellent shape and have never been painted, an H & C colored stain might be the solution.

THE ONE DAY INSTALL! what to know.

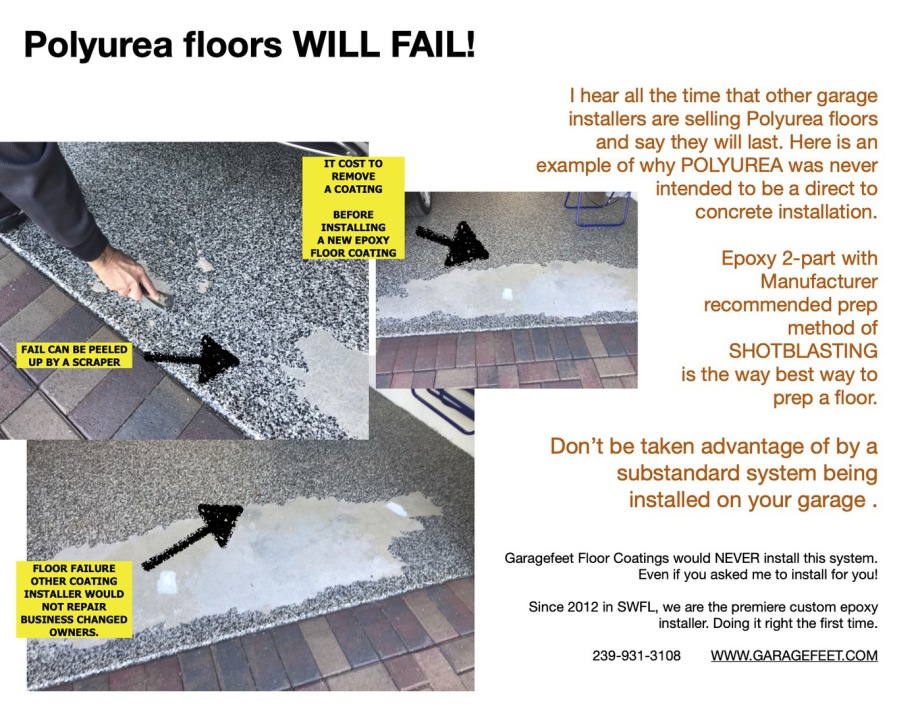

I was told that I could get a floor installed in -1- day. You can, but it won't last.

Polyurea, like all urethanes, were never designed as primers for floor coatings. And although diamond grinding is an accepted method of floor prep, it is nowhere near the best.

All flooring coatings manufacturers recommend shot blasting as the BEST prep method for coatings.

The only benefit to using polyurea as a primer and base coat is that it cures extremely fast, allowing one-day coating systems. This system may look good for a short while; however, it will eventually come off the floor because the floor is too smooth and the coating cannot penetrate into the concrete. It is also susceptible to moisture vapor transmission, which may "dome" or "bubble" the floor.

A company that uses one day installs of polyurea makes a lot of money because they only have to buy one type of coating and they make only one trip to the project site.

Garagefeet Floor Coatings use the tried and true method of shot blasting floors, creating a NON-SMOOTH surface for our penetrating MVT barrier epoxy to get a good anchor to the floor that is unlikely to EVER release. It takes longer and requires more labor and specific coatings for specific floors.

We always sleeps well at night because we know our floors stick.

I am going to do it myself.

Many clients buy the "BIG BOX STORE" epoxy and try it themselves. I will say that the time you spend getting the materials and installing takes more time than you will think. In addition, the floor will come up in time. However, if you are compelled to do it yourself let us make a recommendation to SHOTBLAST your floor which is always the recommended prep method to all epoxy coating jobs. For $2.00 sf we will come out and prep the floor so it is ready for your coating. A typical 2 car garage will take approximately 2-2.5 hours to shot blast.

DUMP TRAILER availability

If I want to clear out a house and it just have it disposed of, what can you do for me before you start working on the floor?

Garagefeet Floor Coatings has a dump trailer and we can help you empty the house and take it to the dump. Rent the trailer and 2 employees per hour to unload the area and take it to the dump.

Hourly charges and dump fee's apply.

How much dust does grinding make?

About coatings. This is so confusing.

|

What is? |

Definition |

Uses |

|

Polyaspartic |

A polyaspartic coating is a protective layer of aliphatic polyurea that is applied to metal or concrete floor surfaces. The surfaces are layered by spraying, painting or plastering to prevent corrosion and erosion. |

Top coat needing additional UV protection, Dry’s more quickly. |

|

Epoxy |

An epoxy is a thermosetting polymer that possesses unique mechanical and resistance properties. The term epoxy can be used for the cured end product or any of the basic components within epoxy resins. An epoxy resin is a class of thermoset polymer made from a monomer that contains at least two epoxide groups. Epoxies are thermoset plastics made by the reaction of two or more industrial chemical compounds. Epoxy resins are used in a wide array of consumer and industrial applications because of their toughness, strong adhesion, chemical resistance and other specialized properties. |

Tough coating used for concrete, wood, and other surfaces. Chemically cured. |

|

Urethane |

Urethane is a type of finish that is applied to many products. It provides protection against weathering, scratches and temperature. Urethane is a sealer that is used to protect many types of products, but is most often used to seal decorative concrete and stone. |

Chemical resistant top coat that is used for area’s needing heavy duty protection. UV protection. Dry’s in 18-24 hours |

|

Backer rod |

A backer rod is a cylindrical type of foam used to fill cracks and gaps between building materials |

Fills in the concrete cuts/expansion joints making a smooth transition while keeping the joint intact. |

|

Epoxy Paste |

formulated for repairs to concrete and for anchoring applications |

Fills cracks and divots before any coating is installed. Makes for a smooth surface. |

|

Polyurea |

Polyurea is a subgroup of polyurethane. Like epoxy, it's a 2-component product (Part A and Part B). When the two parts are mixed, they quickly catalyze (“cure”) and produce a mixture that becomes very hard, very quickly. The mixture has low to no volatile organic compounds (VOC's) and is more flexible than epoxy. |

Just another name for epoxy. Cures fast. Flexibility is a concern for highly traffic’d area. |

|

Shotblasting |

Shot Blasting is a surface treatment process using high velocity steel abrasive. Shot blasting is method through which it is possible to obtain excellent cleaning and surface preparation for secondary finishing operations. |

Preferred method of prep for all coatings manufacturer’s. Preps floor > CSP 3-4 |

|

|

|

Method of prep. Preps floor. <CSP 1 |

|

Sanding |

Sanding is the process where by there are sanding disc’s attached to the grinder to smooth the surface. |

< CSP 0 |

|

Acid Etching |

Acid etching is the process of applying hydrochloric/muriatic or buffered phosphoric acid to a slab, then rinsing it off with water. |

Manufacturers no longer recommend acid etching. |

How much dust does grinding make? If using a HEPA vacuum system, not as much as you would think. See below.

CALL FOR A FREE ESTIMATE TODAY!

Garagefeet Floor Coatings, LLC

8181 Bayshore Rd.

North Fort Myers, Florida. 33917

Phone: 239-931-3108

Email: info@garagefeet.com

Located off I-75, Exit 143, then West for 1/2 mile on Bayshore. On the right before the railroad tracks.

CALL Garagefeet Floor Coatings, LLC

239-931-3108 today! We are your epoxy, urethane, rubberized flooring specialist in Southwest Florida.

Serving ALL of SWFL, including Lee, Collier, Charlotte, Hendry, Desoto, Glades, Sarasota counties

Licensed and Insured!

DC13-00379

LCC20130004166

HC15-0100.SP

AAA-14-00096

1400056

HCR005847

GAWC543152

CERT-0080-2020